Electric Torque Motors: Driving Precision and Efficiency in Industrial Applications

As industries continue to demand higher productivity, precision, and energy efficiency, electric torque motors have become an essential component in various industrial applications. These specialized motors are designed to provide precise control of torque with minimal speed, making them an ideal solution for processes that require consistent, reliable performance. For manufacturers seeking such solutions, partnering with a trusted Electric Torque Motor Supplier is crucial to ensure optimal performance and integration.

What is an Electric Torque Motor?

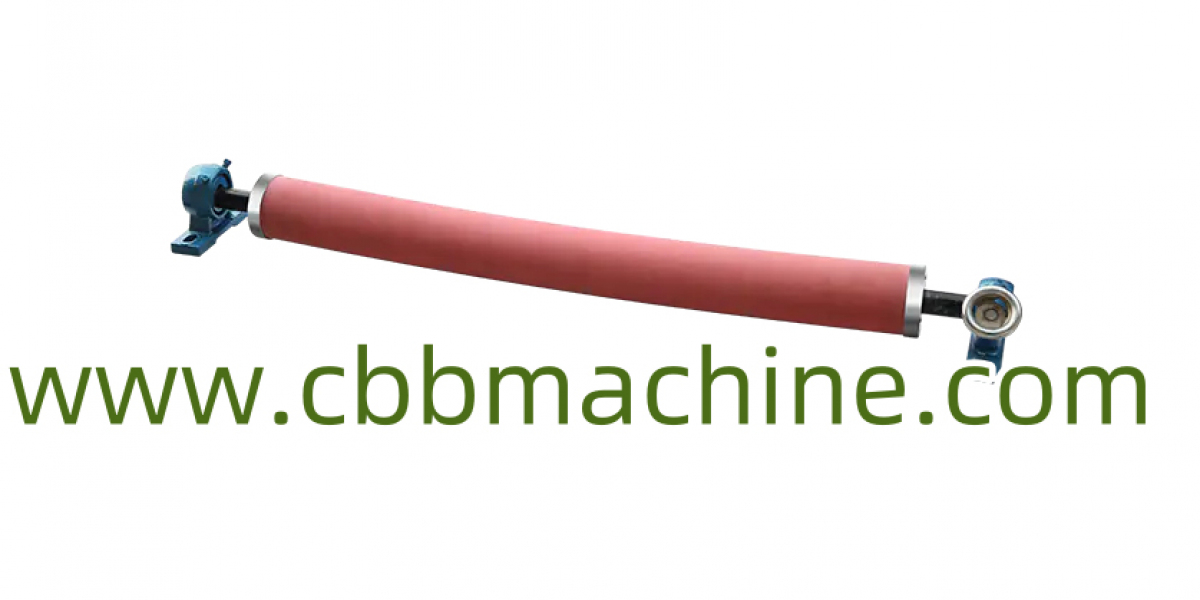

An electric torque motor is a type of direct-drive motor that generates continuous torque without the need for additional gears or transmission systems. Unlike traditional motors that rely on speed to drive machines, torque motors provide a constant level of torque, which is ideal for applications requiring high precision and low-speed operation. Their design allows them to eliminate mechanical losses often associated with gearboxes and other transmission components, providing greater energy efficiency and reliability.

These motors are used in a variety of applications where maintaining smooth and accurate torque control is essential, such as in printing, packaging, robotics, and textile manufacturing. With their versatility, electric torque motors are becoming a popular choice for industries looking to optimize their machines and production processes.

Key Benefits of Electric Torque Motors

Precise Control and Reliability

Electric torque motors are known for their precision. Unlike traditional motors that may experience fluctuations in torque, electric torque motors can maintain a steady and consistent torque throughout the operation. This precision makes them ideal for applications where smooth and controlled motion is critical, such as in printing presses, packaging lines, and automated manufacturing processes. By working with a reliable Electric Torque Motor Supplier, companies can ensure they receive motors that meet their specific torque and control requirements.

Energy Efficiency

One of the standout advantages of electric torque motors is their energy efficiency. Traditional motors often require additional components like gearboxes, which can result in energy loss due to mechanical friction. In contrast, electric torque motors provide a direct drive, minimizing energy losses and improving overall efficiency. As industries focus on reducing energy consumption and lowering operational costs, electric torque motors present a sustainable solution for businesses looking to reduce their carbon footprint while enhancing productivity.

Low Maintenance and Durability

Another key advantage of electric torque motors is their low maintenance requirements. Since they don’t rely on external gearing systems, there are fewer components that can wear out over time. This results in reduced maintenance needs and lower costs associated with repairs and part replacements. Additionally, the absence of gearboxes means fewer mechanical failures and less downtime, leading to improved uptime and productivity. When working with an Electric Torque Motor Supplier, businesses can ensure they receive motors that are built for durability and longevity.

Compact Design

Electric torque motors are designed to be compact, which makes them ideal for applications where space is limited. Their direct-drive nature eliminates the need for bulky gears or external components, making them easier to integrate into existing systems. This space-saving design is especially beneficial in industries such as packaging and automation, where efficient use of space is critical.

Smooth and Quiet Operation

In addition to their precision and energy efficiency, electric torque motors are also known for their smooth and quiet operation. This makes them an excellent choice for environments where noise and vibrations need to be minimized, such as in food processing or pharmaceuticals. By reducing noise and vibrations, electric torque motors contribute to a more comfortable and productive working environment while also reducing the risk of mechanical stress on surrounding equipment.

Applications of Electric Torque Motors

Electric torque motors are used in a wide range of applications due to their high precision and reliability. Some of the most common applications include:

Packaging: Electric torque motors are used in packaging lines to maintain consistent tension in films, labels, and packaging materials. This ensures smooth feeding and accurate packaging without material damage.

Textile Manufacturing: In textile machines, torque motors regulate the tension of yarns and fabrics, preventing defects such as stretching or tearing. Their precise control ensures high-quality fabric production.

Printing: Electric torque motors are used in printing presses to maintain consistent paper tension during printing, ensuring high-quality prints and accurate color registration.

Robotics: In robotics, torque motors are employed in robotic arms and other automation systems where precision movement and consistent torque are crucial for accurate assembly and material handling.

Food Processing: Torque motors drive wrapping, sealing, and packaging machines, providing precise control for smooth, accurate, and hygienic food handling.

How to Choose the Right Electric Torque Motor Supplier

Choosing the right Electric Torque Motor Supplier is essential to achieving the desired performance, efficiency, and reliability in your production lines. Here are some key factors to consider when selecting a supplier:

Industry Expertise: A supplier with experience in your specific industry will better understand your needs and offer motors that are tailored to your requirements. Whether you're in packaging, printing, or robotics, an experienced supplier can help guide you toward the right solution.

Customization Options: Every application is unique, and a one-size-fits-all approach may not be suitable for all situations. Look for a supplier who offers customized solutions, allowing you to select the ideal motor specifications for your specific needs.

Quality and Reliability: Ensure that the supplier provides motors that meet industry standards and have been tested for durability and performance. High-quality motors will last longer, require less maintenance, and deliver consistent results.

Customer Support and Service: A reliable supplier should provide excellent customer support, including installation guidance, troubleshooting assistance, and after-sales service. This ensures that you can get the help you need if any issues arise with the motors during operation.

Conclusion

Electric torque motors have become an essential technology in industries requiring precise control, efficiency, and low maintenance. Their versatility and reliability make them suitable for a wide range of applications, including packaging, textiles, printing, and robotics. By choosing a trusted Electric Torque Motor Supplier, businesses can ensure they are investing in high-quality motors that will optimize their operations, reduce costs, and enhance productivity. With the right motor supplier, companies can take advantage of the many benefits these motors offer and stay competitive in today’s fast-paced manufacturing environment.